Pallet Storage Reimagined: Which Solution Really Suits your Smart Warehouse

Rising volumes, a shortage of skilled workers and shrinking storage space – the demands on intralogistics are growing faster than the available square metres. Pallet storage is evolving from a simple stock warehouse to the dynamic core of the supply chain. To remain competitive today, one must avoid thinking in terms of individual components. A comprehensive, well-networked solution that combines scalability and digital transparency is essential.

From Warehouse to Logistics Strategy: What Really Matters in Planning

Choosing the right pallet warehouse does not start with the technology, but with the specific requirements of your company. The decisive factor is which solution optimally supports your processes today while leaving room for future developments.

- Inventory and item structure: How high is the number of SKUs in relation to inventory depth? While many items with small inventories require fast and direct access, items with high pallet inventories primarily require the densest possible storage.

- Dynamics & throughput: Is it a matter of a quiet stock buffer or high-performance processes with extreme peak loads in order picking?

- Structural conditions: Ceiling heights and inventory areas limit the choice, especially in brownfield projects. Systems that save 30–50% space compared to manual warehouses are often the deciding factor here.

- Process integration: A modern pallet warehouse must communicate seamlessly with ERP and production systems to guarantee 100% traceability and synchronised material flows.

Three Technologies, One Goal: The Optimal Solution for your Throughput

GEBHARDT offers three pallet storage solutions that address different logistical priorities, from classic stock storage to highly dynamic, scalable applications.

GEBHARDT Storage and Retrieval Machines

GEBHARDT storage and retrieval machines for pallets are the proven solution for automated warehouses with high capacity requirements and clearly structured inventory profiles. They enable direct access to each pallet and are particularly suitable for warehouses with many SKUs and predictable throughput requirements. Typical areas of application are stock and buffer warehouses, distribution centres and production warehouses where stability, availability and long-term use are paramount. Thanks to the use of large construction heights, space can be optimally utilised, while the robust technology ensures high process reliability in 24/7 operation.

GEBHARDT StoreBiter® HDS

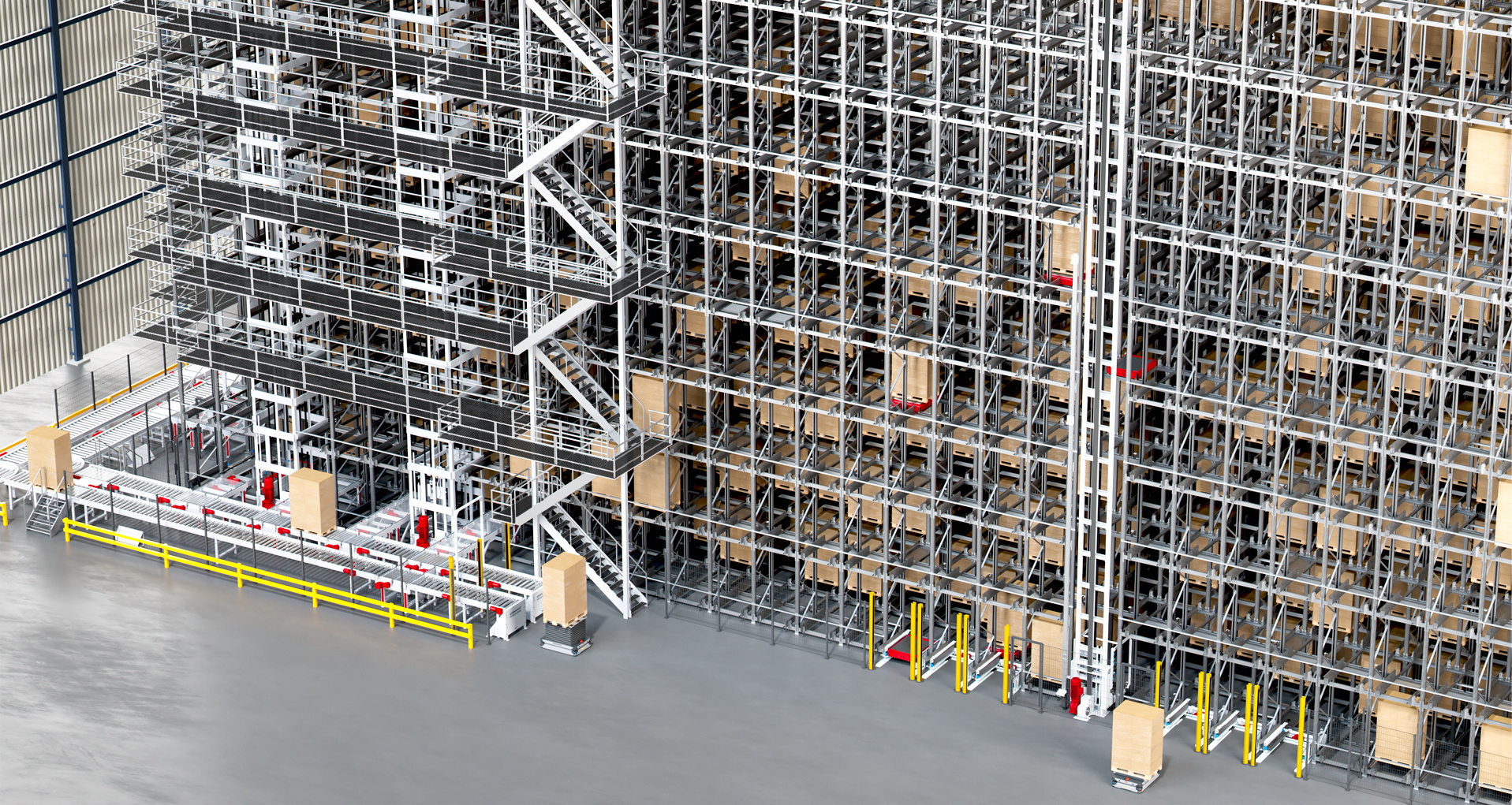

With the GEBHARDT StoreBiter® HDS, GEBHARDT offers a high-density shuttle solution for applications with high throughput and dynamic material flows. The system is designed to move many pallets in parallel and is particularly suitable for applications with multiple pallets per SKU and pronounced peak loads. Through the parallel operation of numerous shuttles, the StoreBiter® HDS achieves high throughput while maintaining high system availability. Performance is largely independent of pure storage capacity – a decisive advantage for production supply, FMCG, 3PL or retail logistics. In addition, the system can be expanded modularly and adapted step by step to increasing requirements.

GEBHARDT Omnipallet®

GEBHARDT Omnipallet® stands for maximum flexibility in pallet warehousing. The solution combines high storage density with the ability to scale throughput and performance independently of capacity. This makes the GEBHARDT Omnipallet® particularly suitable for companies with fluctuating volumes, seasonal peaks or growing business. The use of parallel shuttles allows performance peaks to be cushioned in a targeted manner without changing the entire warehouse layout. At the same time, it is ideal for brownfield projects where existing buildings must be used optimally and expansions must be implemented step by step. The solution can be flexibly connected to production, order picking or cross-docking processes.

Theory Meets Practice: Maximum Efficiency through Tailored Pallet Storage Concepts

KW automotive: ‘Efficiency instead of congestion’ in the fast lane For chassis manufacturer KW, the main challenge was to network the entire intralogistics process – from goods receipt to dispatch – in a ‘built-to-order’ production system.

The solution: GEBHARDT implemented a complete system that centrally and easily controls complex intralogistics processes, including a single-aisle automatic pallet warehouse (APL) operated by a StoreBiter OPS on a GEBHARDT Cheetah Heavy storage and retrieval machine. The result: thanks to automation and control via GEBHARDT StoreWare, KW has achieved significantly shorter throughput times and a high level of process reliability. ‘We can already see a very good return on investment,’ summarises Klaus Wohlfarth.

SEW-EURODRIVE: Full flexibility for Europe's most modern electronics factory In Bruchsal, the market leader in drive technology was looking for a modular and Industry 4.0-compatible logistics concept for production supply. The solution: At the heart of the system is a combined GEBHARDT StoreBiter MLS and Omnipallet warehouse. The APL comprises 16 levels and is operated by 31 autonomous robots (Omnipallets), which efficiently manage over 9,700 storage spaces for pallets and mesh boxes. The result: the direct connection to driverless transport systems (AGVs) enables fully automated, demand-driven production supply. The system is not only powerful, but also expandable at any time thanks to its modular design.

Why the Right Pallet Warehouse Today Determines your Success Tomorrow

A modern pallet warehouse is much more than just a storage location; it is a strategic tool for coping with market pressure. Investing in automation today not only solves the space problem or the shortage of skilled workers. They are also laying the foundation for a transparent, scalable supply chain. With GEBHARDT, you are investing in a complete system that will grow with your requirements over decades thanks to modular retrofit options. The solution was not developed around a single system, but rather along the lines of processes, growth targets and operational conditions – with the pallet storage system as an integral part of a smart overall system.